Welding technique of aircraft pylon

“Sukhoi civil aircraft”, Komsomolsk-on-Amur, Russia.

Because electron beam welding is done in vacuum, there’s no atmospheric gas contamination. This results in the cleanest, highest-quality weld possible. For parts that require post-weld testing such as x-raying, EB welding is your best option.

One of EBW’s greatest advantages is its ability to weld materials with different melting points, such as copper to stainless steel. From a cost and performance perspective EB welding also has the ability to weld high-cost nickel alloys to relatively low-cost stainless steel.

such as titanium, niobium, and tantalum. Since electron beam welding is done in a vacuum chamber, it prevents the exposure to oxygen that can cause these welds to fail. This is particularly an issue with welding titanium – if the welds are exposed to oxygen, it can cause a serious failure called alpha casing.

EBW has high strength with minimal distortion or damage. Also, very little post-weld machining is needed due to its accuracy, making it suitable for welding precision parts. Since the machine is programmable, it is possible to have custom weld-profiles.

Because of the low heat input of electron beam welding, temperature-sensitive parts can be located in proximity to the weld region.

Electron beam welding is about 90 percent efficient – meaning 90 percent of the input power is reaching the part. That’s more important to us as welders rather than you the customer, but it’s another reason to prefer EB welding.

Volume of chamber is not exceed

10 m3

Electron gun is placed outside the chamber.

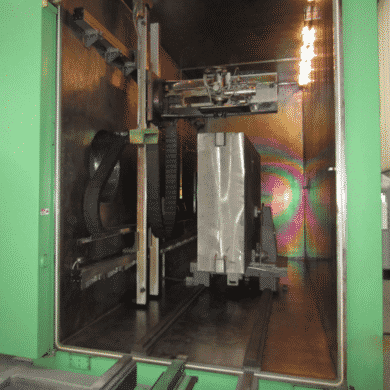

Operational pressure is 5×10-4 mbar. The parts to be welded are moved by a high-precision manipulator located inside the chamber

Volume of chamber is up to 50 m3. Electron gun is placed inside the chamber. Operational pressure is 5×10-4 mbar. The parts to be welded and the gun are moved inside the chamber by a high-precision manipulator in 3D dimensions and rotation

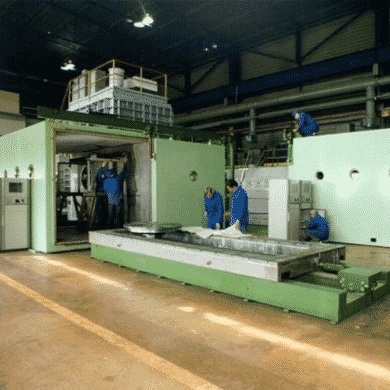

Volume of chamber is more then 50 m3.Accelerating voltage is 60 kV, electron beam current is up to 1000 mA. Operational pressure is 5×10-4 mbar. The parts to be welded and the gun are moved inside the chamber by a high-precision manipulator in 3D dimensions and rotation

3-gun machines for welding of drill bits. Equipment for welding of the thick steel slabs. Machines for the granule metallurgy. Machines for welding of tube plates. High-Voltage power supply. System for stabilization of focus of electron beam

Regular maintenance of your equipment. Repair and modernization of the equipment. Modernization of obsolete equipment.

Job-shop from prototypes to serial production – your resources will be relieved and your efficiency will be increased.

We help and advise you from producing prototypes to high volumes.

Big chamber

Big chamber

chamber - 98 m3

accelerating voltage - 60 kV

power - up to 60 kW

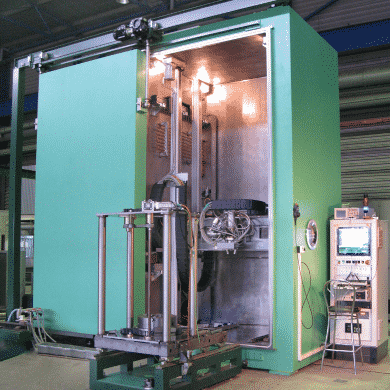

Medium chamber

Medium chamber

chamber - 22 m3

accelerating voltage - 60 kV

power - up to 60 kW

Medium chamber

Medium chamber

chamber - 20 m3

accelerating voltage - 60 kV

power - up to 60 kW

Medium chamber

Medium chamber

chamber - 10.5 m3

accelerating voltage - 60 kV

power - up to 60 kW

Medium chamber

Medium chamber

chamber - 40.5 m3

accelerating voltage - 60 kV

power - up to 60 kW

Small chamber

Small chamber

chamber - 3 m3

accelerating voltage - 60 kV

power - up to 30 kW

Small chamber

Small chamber

chamber - 6 m3

accelerating voltage - 60 kV

power - up to 30 kW

Special Project

Special Project

chamber - 50 m3

accelerating voltage - 60 kV

power - up to 60 kW

Special Project

Special Project

Machines for the degassing, filling and vibration compaction of the granules in the capsules with subsequent hermetic sealing by means electron beam welding

Zoom in

+

+

Established in 2010, Beamtechnology s.r.o. is the most trusted provider of advanced welding systems and job shop welding services in the fabrication market. Our wide selection of electron beam welders, electron beam additive manufacturing solutions makes us the most versatile welding solutions supplier on the market. Beamtechnology s.r.o. is at the forefront of electron beam welding technology and pioneers of metal additive manufacturing processes, also referred to as 3D printing. We are dedicated to world-class engineering, as well as extensive research and development. When you talk to Beamtechnology s.r.o. about your requirements, you're dealing with the best in the business.